Knitting innovations continue to add value for textile manufacturers during a difficult time.

TWSpecial Report

Courses, wales, loops, gauge, warp, weft, raschel, jersey, interlock … just some of the terms familiar to people working in the knitting industry. Knitting technology comes in a variety of types and sizes and may be used to make all sorts of products from small vascular heart grafts(see “Prototype Graft Designed To Replace Damaged Heart Vessels Shows Promise In Cell Study”,TW,2021年1月/2月), to shoe uppers and apparel fabrics all the way to large-scale bedding components and anything in between that requires comfort, stretch and seamless shaping, among other attributes.

自2019年ITMA以来,ITMA通常为新的创新铺平道路 - 尽管由于大流行而在机械市场上遇到困难,但编织技术制造商仍在创新并帮助其客户提供价值。这是一些可用于编织者的新产品。

Mayer & Cie

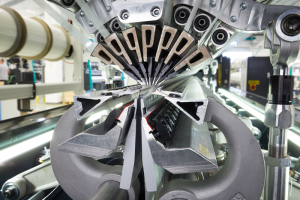

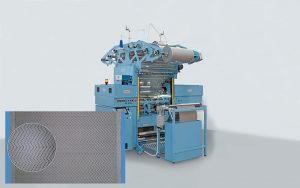

After completing field tests, Germany-based Mayer & Cie reports its OVJA 2.4 EM circular knitting machine now is ready for the market. The fully electronic model is designed for mattress cover fabrics with high output and a wide pattern variety. This ready-for-market version builds on the model introduced during ITMA 2019 with the addition of a new thread fluctuation control system positioned on every second feeder. A controlled air stream maintains constant yarn tension especially at high revolutions per minute, which helps avoid thread loops and dropped stitches.

Mayer&Cie的区域销售经理Thomas Zizmann说:“以2.4的馈线密度为2.4 OVJA 2.4 EM级数,其当前趋势越来越高。”每小时的织物。如950年的速度系数所示,这显然是世界上同类产品中最有生产力的机器。”

Relatively new to the mattress market, knitted fabrics have taken off over the last 20 years according to Mayer & Cie in part because of their elasticity and flexibility. However, the market is increasingly competitive, and Mayer & Cie. aims to add value for its customers — mostly premium manufacturers in the United States and Belgium in this sector — by increasing the production output of its mattress machines.

Mayer & Cie also offers the OVJA 1.6 EE/2 WT double jersey jacquard machine for multi-colored designs and microstructure elements including tuck structures, spacer fabrics and double-knit fabric with a lay-in thread. The machine features three-way electronic needle selection in the cylinder and two-way technology in the rib dial. When special needles are employed, the machine can knit yarns up to 1,200 denier in gauges as coarse as E16. Applications include mattress covers, upholstery, transportation seat covers, shoe uppers and outerwear.

In keeping with the digitalization trend, Mayer & Cie. also offers a cloud- and web-based digital solution for the knitting industry via its knitlink technology. knitlink records data from each machine and provides operators with a visual record of the data on a personalized dashboard.

my.shop was recently launched in selected countries, and a web shop for spare parts will be widely available in the near future, according to the company. Additional functions also are in development.

卡尔·梅耶(Karl Mayer)

在业务方面,2020年德国的Karl Mayer Textilmaschinenfabrik Gmbh收购了H. Stoll Ag&Co。Kg。,这是在扁平编织舞台上的既定名称。购买范围扩大了卡尔·梅耶(Karl Mayer)的产品,包括翘曲编织和扁平针织解决方案。Stoll现在是Karl Mayer Corporate Group中的独立业务部门。

In the United States, the Stoll and Karl Mayer North American subsidiaries were consolidated into one location in Greensboro, N.C. An investment at the site, scheduled for completion in March 2021, includes a state-of-the-art textile development and visitor center, which offers demonstrations, training, collaboration opportunities with industry partners, prototyping and an assembly operation for both Karl Mayer and Stoll technologies. Stoll’s core team in Greensboro offers business and technical management, textile design and product development, machine programming and customer service.

“With the new development and visitor center and the synergies that come with combining our capabilities, we offer textile producers and all industries that can imagine the use of textiles an extremely strong resource in North America” said Tony Hooimeijer, president of KARL MAYER North America.

The company also has created a Textile Makerspace platform intended to help connect the textile industry with new technologies to encourage innovation. One focus, Textile Circuit, looks at smart textiles and wearables, and projects are underway at the company’s headquarters in Obertshausen, Germany. The Greensboro location also offers aMakerspacearea with a modified standard machine and competent service technicians, according to the company, where U.S.-based customers can develop and implement ideas for e-textiles with support from Sophia Krinner, textile technology product developer, who was charged with setting up Textile Circuit. “Customers can come to us with their ideas and work with us to try out different ways to make their ideas a reality,” Krinner noted.

On the technology side, Karl Mayer offers some new technologies for the knitting sector. Its RD 7/2-6 EN double needle bar raschel machine offers up to 30-percent higher speed compared to its predecessor the RD 7/2-12 EN, according to the company. First introduced in 2019, the machine can knit 3D fabrics using a trick plate distance of 2 to 6 millimeters. Its EN pattern drive and maximum shogging movement of 1 inch allow patterning variety with up to 12,000 stitch repeats. The machine is available in working widths of 138 and 77 inches in gauges E 18, E 22 and E 24. Fabrics may be used for footwear, clothing and mattress applications.

卡尔·梅耶(Karl Mayer)的HKS 3-m开发是与公司数字解决方案相关的第一批机器之一。该机器可以直接从KM.ON安全云下载模式数据,并且不需要使用图案磁盘,从而可以在与N模式驱动器相关的速度下使用EL Gears找到简单的图案更改。该公司的说法,该机器最近以300英寸的更宽或并排生产的范围更宽的工作宽度发行,并且比其前身快15%。

卡尔·梅耶(Karl Mayer)offers three interchangeable options for purchasing lappings for the HKS 3-M ON — SwapKnit 36 and SwapKnit 36 Flat for designs up to 36 stitch courses; as well as a variant developed for pattern repeats of more than 36 stitch courses. Patterns for the machines are downloaded from Karl Mayer’s Webshop Spare Parts and loaded on to the knitting machine for fast and flexible pattern changes. According to Karl Mayer, the hybrid machine combines the patterning possibilities of a typical N and EL pattern drive in a single machine.

卡尔·梅耶(Karl Mayer)offers three interchangeable options for purchasing lappings for the HKS 3-M ON — SwapKnit 36 and SwapKnit 36 Flat for designs up to 36 stitch courses; as well as a variant developed for pattern repeats of more than 36 stitch courses. Patterns for the machines are downloaded from Karl Mayer’s Webshop Spare Parts and loaded on to the knitting machine for fast and flexible pattern changes. According to Karl Mayer, the hybrid machine combines the patterning possibilities of a typical N and EL pattern drive in a single machine.

Shima Seiki

在SARS-COV-2大流行的早期,总部位于日本的Shima SeikiMfg。Ltd.发布了可以使用各种编织机(包括WholeGarment®技术)生产的口罩的免费编织数据。目的是帮助寻求将生产转换为面具的Shima Seiki机器所有者,以尽快减轻手术面具的短缺。这些图案适用于3D形式的面具,其具有整体耳环的整体式面具,可以在一步中编织,而无需进一步缝制。这些设计可在Shima Seiki的用户网站上找到,位于Shimaseiki.com/user/samplesearch上。

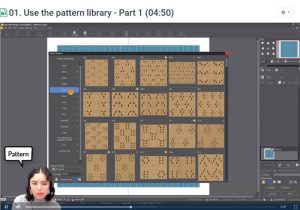

Officially launched in September 2020, Japan-based Shima Seiki Mfg. Ltd.’s yarnbank™ online web service allows users to search and view the latest yarns from a wide variety of companies around the globe, and then download the yarn data for use by fabric simulation and virtual sampling on the Shima Seiki SDA®-onE APEX4 design system. The goal is to give designers the ability to create accurate representations of garments that may be created using yarns that are available for production.

Existing Shima Seiki APEX users can register to use yarnbank free of charge. In October 2020, the company also launched a subscription-based design software option named APEXFiz™. This offering breaks with Shima Seiki’s tradition of offering only all-in-one proprietary hardware and software packages and allows customers to install the software — available in five different configurations: Design Jr.; Design-Standard; Design-Knit; Design-Weave; and Design Pro — on their individual computers. APEXFiz users also have access to yarnbank.

Shima Seiki reports it “has traditionally promoted design simulation and virtual sampling as an essential part of its ‘Total Fashion System’ concept wherein virtual samples replace physical samples in an effort to reduce time, cost and materials wasted in the sample making phase, further realizing overall efficiency and reduced waste for a sustainable manufacturing supply chain.”

纱线公司可以根据多种计划在Yarnbank上注册其产品。根据Shima Seiki的说法,纱线制造商的优势是“直接向客户展示其纱线”的能力。Yarnbank技术可以通过减少对传统样品销售的依赖来节省纱线制造商的时间,成本和材料。

Shima also recently released the SHIMANAVI™ e-learning system that provides online training for its APEX series users. The flexible system offers support at the user’s pace when and where it is convenient. Several of the courses are available in multiple languages.

来吧

意大利的JakobMüller集团公司COMEZ Internationl S.R.L.最近的一些技术介绍包括DNB/600-2B,DNB EL-32和800 ACO/EL。

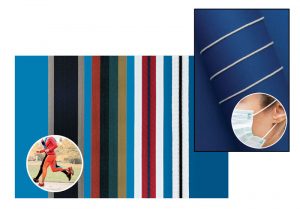

The DNB/600-2B is a high-speed mechanical double needle bed warp knitting machine designed for mass production of items including ear loops for masks and sportswear accessories. The low stitch density required for such articles and high operating speed of the machine equate to very high productivity, according to Comez. Equipped with two mechanically controlled guide bars, the DNB/600-2B can process all types of yarn into double face fabric structures. A compact design and reduced working width result in fast changeovers.

公司的DNB / EL-32-12B,首次引入at ITMA 2019. The electronically controlled warp knitting machine is designed for sample production using any yarn in all possible gauges on a single, compact machine. Items that may be produced using the DNB/EL-32-12B include technical textiles, medical textiles, shoe uppers and apparel textiles. The machine’s 12 guide bars and electronic long-throw device with a maximum stroke of 560 millimeters allow more advanced technical fabrics to be produced such as reinforced fabrics, fabrics with continuous weft insertion and technical furnishing fabrics.

COME的800 ACO/EL钩针编织机具有复合针,电子控制的纱线张力和针迹密度调节。COMZ报告说,该机器适合生产弹性和刚性织物和磁带,非常适合需要锁紧缝线结构,例如医疗和骨科纺织品,闭环Astrakhan风格的面料,提供的丝带和胶带,以及运动服丝带等文章。该机器配备了八个纬线,可提供800毫米的工作宽度。

Groz-Beckert

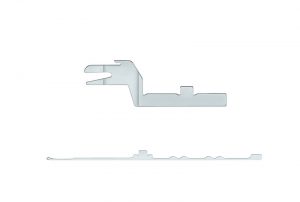

Germany-based Groz-Beckert KG recently introduced the SANT™ SF special application needle and Sinker SNK SF for use when knitting staple fiber yarns with increased fiber fly on large diameter circular knitting machines. In such manufacturing processes, fiber residue, fiber abrasion and dirt can cause deposits in the channels of the needle carrier channel that eventually result in uneven needle seating, tight movement and needle and sinker overheating, which leads to poor quality fabrics and damage to the machine components. The SAN SF needle and SNK SF sinker were designed to reduce dirt accumulation and extend required cleaning intervals to reduce machine downtime.

The staple fiber needle features a closed shank on the back of the needle, and cushions to support the cylinder walls. According to the company, the needle also enhances uniform loop structure.

The sinker has an opening in the front area for lint removal that creates a self-cleaning effect. Use of the sinker reduces fabric defects and wear on machine parts.

Groz-Beckert的新功能也是其学院的移动编织。该公司通过增加了可以从任何地方访问的在线研讨会,扩展了其Groz-Beckert学院。

Groz-Beckert的新功能也是其学院的移动编织。该公司通过增加了可以从任何地方访问的在线研讨会,扩展了其Groz-Beckert学院。

目前,一种新的在线研讨会的年代econd Tuesday of each month. Seminars are live and interactive, and attendees can ask the presenter questions using the chat function. The March seminar is titled “Reduced costs when knitting on large diameter circular knitting machines.” The planned April session is named “Needle handling — Correct cleaning of flat needles.” More information about the seminars can be found at the company’s website.

January/February 2021