Trützschler’s TC 19i was engineered for energy-efficient carding

Trützschler’s TC 19i was engineered for energy-efficient carding

TWSpecial Report

Global energy consumption reached a record high in 2019, following a 40-year trend for rapidly increasing energy demand that was only halted by the coronavirus pandemic.1 It’s estimated that more than 80 percent of this energy is still generated from fossil fuels that produce carbon dioxide emissions and contribute to climate change.2 Renewable energy offers a solution to this problem, but saving energy whenever possible is an even more effective approach. That’s why Germany-based Trützschler GmbH & Co. KG has developed the intelligent card TC 19i, which sets a new benchmark for energy-efficient carding, according to the company.

The intelligent Trützschler card TC 19i features the unique T-GO gap optimizer, which continuously and automatically monitors and adjusts the carding gap to an ideal position during production. As of now, more than 2,000 intelligent cards sold worldwide prove quality and production leaps in the double-digit percentage range daily, thereby reducing energy demand per kilogram produced.3 Innovative drive and air technology further reduce energy consumption of the TC 19i. In this way, the TC 19i saves energy to help protect the planet — and also boosts profitability for yarn production.

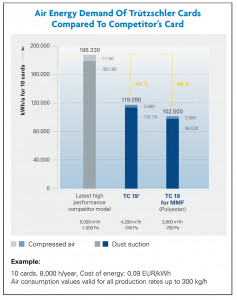

The most energy-intensive elements in a carding machine are the drive, the dust suction process and the compressed air system. Permanent suction is needed to remove dust and cotton waste in key places. In contrast to Trützschler cards, many cards on the market also use compressed air for suction hoods in the pre-carding and post-carding areas, for example. Smart optimization of these areas has made the intelligent card TC 19i a benchmark for energy efficiency in carding because it uses less electricity, lower suction pressure and less compressed air than other machines, while providing the highest production rates currently available on the market.

在TC 19我之间进行比较d a high-performance card from a competitor, the TC 19i consumed at least 10-percent less energy per kilogram of material produced when manufacturing rotor yarn from a cotton and cotton waste mix. The compared energy values included electric power consumption and energy required for suction and compressed air and were measured in both cards at the same production of 180 kilograms per hour (kg/h). A 10-percent reduction in energy per kilogram of sliver produced, as proven here by TC 19i, can have a significant impact on a spinning mill’s profitability; annual savings worth a five-digit sum are frequently possible, depending on factors such as the output of the mill. The customer trial also showed TC 19i’s excellent reliability at the customer’s usual production rate of 180 kg/h, and even demonstrated stable performance at 300 kg/h in the same application. Because the TC 19i with T-GO gap optimizer realizes maximum production rates at no compromise in quality, manufacturers can reduce their energy demand and investment costs drastically: Less machines are needed to achieve the desired output, and energy consumption per production is reduced.

Energy-Efficient Air Technology

Energy-Efficient Air Technology

除了提高生产率之外,空气技术在TC 19i的能量平衡中起着关键作用。Trützschler的空气技术负责人克里斯蒂安·弗雷塔格(Christian Freitag)解释了他如何在该领域优化TC 19I:“首先,我们尽可能减少了压缩空气的需求,”他说。“第二,我们降低了吸力和吸力的空气需求。例如,我们所有的空气收集器都经过精心开发,以消除潜在的抵抗力并促进理想的流动。”

通过涉及空气流数学模型以及流量模拟和原型的数学模型,有时甚至具有挑战性的创新过程使这种改进成为可能。通过结合TC 19i中最终优化的零件,Trützschler的专家开发了一张卡,其吸力压力仅为-740 pascals,并且空气需求仅为每小时4,200立方米。与最新的高性能竞争对手模型相比,这转化为空气技术的能源需求减少40%。

“These achievements are fantastic — but we didn’t stop there,” said Ralf Helbig, R&D engineer for Air Technology at Trützschler. “We have also made it possible to further reduce energy demand in polyester applications, which are increasingly important to our customers. In a polyester configuration, the TC 19i can reduce the necessary pressure for waste suction by a further 14 percent because of improvements to elements in the pre-carding and post-carding areas, and the removal of suction hoods. The suction is still just as reliable — but it needs much less energy.”

对环境和资产负债表有益

凭借其独特的Gap Optimizer T-GO,其最先进的驱动器和优化的空气技术,智能卡TC 19i正在领导节能梳理市场。没有其他卡可以在如此高的生产率或一致的质量和能源效率下与其稳定的性能相匹配。结果,TC 19i为全球可持续性做出了宝贵的贡献,并使工厂也更加有利可图。

References:

1 https://www.statista.com/statistics/265598/consumption-of-primary-energy-worldwide/。

2 https://ourworldindata.org/energy-mix。

3增加产量可导致每小时更高的功耗。输出的增加超过了这个因素,因此每公斤产生的卡片片的功耗较低。

2021年9月/10月