德国雷姆切德(Remscheid) - 2019年4月18日 - 在家,工作,街上,天空,水上,甚至在太空中,技术纺织品和无编织者都在朝着惊人的应用程序中的更高表现摇摆。多功能和轻巧,但有时比金属更强大,这些未来的材料从精确协调的纺织系统的相互作用中获得了超级大国。在2019年5月14日至17日在Frankfurt Am Main的TechTextil在B06厅3号厅,Oerlikon将显示由聚酯,聚丙烯和公司制成的化学纤维应用以及它们在这些领域中可以做的。但是,这些展览只是结束的交流手段,因为Oerlikon主要有兴趣将相关的机械和工厂解决方案放置在与贸易公平访问者讨论的中心。

More than two thirds of all technical innovations are directly or indirectly based on new materials, says the German Research Ministry. One could add: The key to a more advanced world, for technological products with amazing functions, breathtaking performance and greater environmental benefits, is also to improve the properties and processing of materials. This applies first and foremost to textiles. Probably no other fabric is so strong as a “team player” who draws its strength from its cohesion.

例如,单个聚酯线看起来不明显。然而,在最深的水域中,高强度的高模量/高固定纤维锚浮动油平台被加工成大腿厚的特殊编织。这些长的“系泊绳”承受着超过1,000吨的破裂负荷,并且比钢的完成任务更好。几十年来,Oerlikon Barmag一直提供特殊解决方案,用于生产为全球客户量身定制的所谓工业纱线(IDY)。“我们将再次在本贸易展览会上展示许多创新,以激发我们的客户,”博士解释说。外交-Chem。Roy Dolmans,技术经理Idy和R&D细丝处理。

Strong and light fabrics make you mobile

但是,正如汽车安全带的制造所显示的那样,日常纺织品也满足了高需求。他们由无糊状宠物纱制成的特殊织物结构既稳定又可拉伸,可以在发生碰撞的情况下保护车辆乘员,但不会伤害他们。在汽车世界中,化学纤维变得必不可少:德国纺织品研究委员会已经说,每辆汽车都以约30公斤的纺织品行驶。它们在安全气囊,汽车屋顶,内饰,装饰,开关,操作元件,驱动皮带或软管中发现。

“The automotive industry is also interested in low costs when it comes to their use. A prime example of the economic production of technical textiles in the automotive sector is the manufacture of tire cord from HMLS (High Modulus Low Shrinkage) yarns. These precursors made of polyester are extremely tear-resistant, still highly elastic as well as temperature and dimensionally stable,” explains Dolmans. The topic of traceability along the entire textile value chain plays also a major role, especially in the automotive industry. “Thanks to our production and process solutions for our customers and our own DIN ISO certifications, we at Oerlikon can guarantee traceability in the production process at any time,” continues Roy Dolmans.

工业纱线扭成扁平的织物,位于几层橡胶层之间,并稳定道路上的汽车轮胎。谈到道路,技术纱线也在下面工作。土工布的固定并稳定道路和路径构造中的土壤。例如,由宠物纤维制成的柔性表面结构非常坚硬,耐蠕变,并且可以在地下生存数十年。

High-tech membranes made from the fifth building material

Textiles have long since arrived in the construction sector and are increasingly playing a role as the “fifth building material” alongside steel, concrete, wood and glass. Innovative solutions include high-tech membranes made of specially coated polyester fabrics, already used for roofs of football stadiums in Warsaw and Kiev or the international airport of Bangkok.

未来的建筑材料也是无编织的。根据各种制造工艺和组合技术,无编织的纺织织物可以配备各种特性。它们具有耐热性,透气性,同时耐水性,霉菌和脱离性,并用于整个建筑部门的屋顶,绝缘,绝缘,绝缘和排水。Oerlikon Nonwoven提供相应的机器和系统解决方案。但不仅在那里:在医学中,非织造的繁荣是一种廉价的手术礼服或绷带,因为它们充当液体或细菌屏障,但保持蒸发和吸收性,并且不粘在一起。应用范围从过滤,婴儿尿布,湿巾和餐巾到土工布和毛毡地毯。在这里,Oerlikon Nonwoven也遥遥领先。

For the large variety of textile floor coverings, special textured continuous filament yarn made of polypropylene or polyester is particularly suitable: Oerlikon Neumag stands for this as the expert for machine and plant solutions for the production of BCF yarns with a wide variety of properties.

多才多艺的非织造和智能纺织品

Functional clothing textiles are a playground for innovative applications of technical yarns. The spectrum of new developments ranges from breathable tracksuits with living microbial cells that react to moisture fluctuations to smart clothing that uses electronics and sensors to open up previously unknown functions. Smart textiles can generate heat, light and electricity, measure temperature and vital functions, heal wounds and reduce pain, modernize industries and make cars and construction safer or more comfortable.

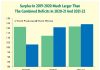

Given this future scenario, it is no wonder that technical textiles, the materials of tomorrow, are on the upswing worldwide. Analysts such as the London market researchers of Future Market Insights estimate that the world market volume for technical textiles will climb from around 166 billion US dollars in 2016 to a good 260 billion US dollars in 2027. This upswing will certainly also drive the market for polyester fibers, which has been growing continuously for many years.

The intelligent processing of such manmade fibers as raw materials is an important foundation for future textile innovations. Market leaders such as the Oerlikon Manmade Fibers segment and its brands Oerlikon Barmag, Oerlikon Neumag and Oerlikon Nonwoven stand for this. Their innovative technologies from melt to yarn, fibers and nonwovens lay the foundation for many of the applications mentioned here – and for ever higher performance, efficiency and quality on the journey to tomorrow’s materials

发布2019年4月19日

Source: Oerlikon Segment Manmade Fibers