TWSpecial Report

m一式纤维耐用,多功能且具有成本效益。这就是为什么它们在过去十年中在纱线产量中变得必不可少的原因,现在占主食纤维消耗的40%以上。Truetzschler通过为人造纤维开发高度专业的机器来支持这一趋势,这些机器不断地满足对质量和效率的期望不断提高 - TC 19i现在正在全球范围内赢得客户。

The intelligent card TC 19i for man-made fibers was launched in 2019 and is now the international benchmark for man-made fiber processing. The results from major textile markets across Asia, Europe and the Middle East speak for themselves: customers were able to increase productivity by between 20 and 100 percent, while also improving quality (IPI) by between 20 and 55 percent.

将怀疑论者变成信徒

Acarsoy Tekstil, a leading yarn manufacturer based in the Bursa province of Turkey, is a strong example of what can be achieved with the TC 19i for man-made fibers. The company has a daily production capacity of 65 tons of yarn across two production facilities, and manufactures a broad portfolio of cotton, linen, polyester, viscose, modal and lyocell yarns. Its processes include ring, compact, air jet, open end, core spun and siro spun technologies. Experts at Acarsoy Tekstil were initially skeptical when Truetzschler TC 19i cards were installed in the second air jet line for 100-percent viscose yarn (Ne 20 to 28). General manager Bülent Değirmencioğlu, as well as his team of operations and maintenance managers, were unsure whether the required level of quality could be maintained when the TC 19i operated at such high speed. However, they were able to produce 60 percent faster with the TC 19i, and clearer cut numbers were 50 percent lower than the first line. In light of these impressive results, Acarsoy is now considering modernizing its other machines too.

BülentDeğirmencioğlu说:“卡是旋转厂的跳动心脏。”“我们知道,我们已经为人造纤维做出了正确的选择,因为它将我们的卓越品质提高到了新的水平 - 同时还可以减少浪费,减少能源消耗并节省人工成本。”

所有人造纤维应用的重大改进

Every single one of the manufacturers that tested the TC 19i for man-made fibers has been able to increase productivity and reduce yarn imperfections compared to predecessor machines. Of course, individual results vary depending on the customer’s specific application, raw material and process – but the TC 19i achieved success every time. This success is largely made possible by the T-GO gap optimizer, which has been specifically adapted to meet the requirements of man-made fiber applications.

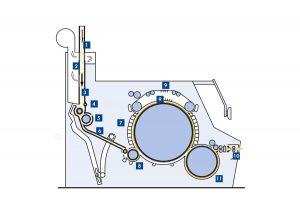

2.不锈钢清洁襟翼

3.不锈钢储备后备箱

4.分段饲料托盘

5. Special opening rollers for higher speeds

6.不锈钢储备后备箱

7. More carding and less cleaning elements

8.用大针辊的WebFeed

9. T-CON 3 and T-GO Gap Optimizer for man-made fibers

10. Additional deflection roller

11.新的Doffer服装TCC Novodoff 3211

“棉花加工,梳一个非常狭窄的差距is often advantageous for the carding result – but this doesn’t apply to man-made fibers” says Christoph Leinders, who was responsible for the design of the TC 19i. “Our T-GO gap optimizer uses advanced, intelligent sensor technology to make sure the machine always maintains the best possible carding gap for the man-made fiber material, blend or application that is being processed. This gives the TC 19i a big advantage over machines from our competitors. We always know the exact carding gap and can adjust it during production using algorithms that we specifically developed for man-made fibers. This means changing environmental conditions or differences in the skill level of the individual operator no longer affect the carding gap setting – so quality levels remain constant.” The T-GO gap optimizer for man-made fibers is as easy to operate as its counterpart for cotton. Only a few clicks on the display are required, and there’s no need for time-consuming flat setting work after each maintenance or re-clothing.

A Winning Combination Of New And Proven Features

通过几个新的和经过验证的功能使TC 19i用于人造纤维的出色性能成为可能。例如,Doffer服装Novodoff 32是由Truetzschler Card Clothing专门为人造纤维开发的,Truetzschler Card Clothing是Truetzschler的子公司,位于德国黑森林地区。它的工程师发明了一种新的工艺技术,该技术使服装更加健壮和耐用,并进一步提高质量,同时减少维护要求。当然,新卡保留了多年来在人造纤维应用中证明其性能的出色功能。簇饲养器中的所有金属板和卡到卡的转移部分均由不锈钢制成,以确保人造纤维的最佳流动。所有覆盖元件的覆盖元件和Doffer均由高精度的Eloxated铝制成。不锈钢滑片管和盘管板可确保在滑动盘盘过程中轻轻的滑动指导。TC 19i的开放前系统具有一个大型卷,具有特殊的针刺和表面处理。与使用常规电线相比,这使您可以将纱线瑕疵(IPI)降低30%,而针头卷的平均寿命比常规卷长二十倍。随着人造纤维对纱线生产的重要性,TC 19i是一款强大的新卡,可在广泛的应用中提供宝贵的性能。 Customers at spinning mills around the world are taking advantage of this new benchmark for man-made fiber processing – and moving ahead of their competitors by increasing productivity, efficiency and quality.

2020年10月22日